Construction

Vehicles

Construction vehicles

International Trade Fair for Construction Machinery,

Building Material Machines, Mining Machines and Construction Vehicles.

All

All

Construction

Vehicles

Construction vehicles

Earth-moving

Earth-moving machines

Road

Construction

Road construction and maintenance equipment

Lifting

Appliances

Lifting appliances and conveyors

Construction Equipment and tools, Formworks and Scaffolds

Pipe & cable laying equipment & tools/Construction equipment, tools and special systems/Formwork and scaffoldings

Mining, Extraction and Processing of Raw Materials

Machines for extraction of raw materials and for mining/Handling of raw materials/Mineral processing (incl. coke oven equipment)

Building Material Production

Handling and processing concrete and mortar at construction sites/Manufacture of cement, lime and gypsum compounds for building materials/Machines and systems for producing concrete, concrete products and pre-fabricated components/Machines and plants for producing asphalt/Machines and plants for producing pre-mixed Dry mortar, plaster, screed and building supply store products/Machines and plants for producing lime sandstone and building products using power plant residue (fly ash, slag, etc.)/Building material handling and packaging (in a plant)

Transmission Engineering and Fluid Technology

Transmission engineering, fluid technology and power generation units

Accessories, Spare and Wear Parts

Accessories and wear parts

Intelligent Management

Digital Construction Site and Job Safety/Services/Test, measurement and process control engineering/Communication and navigation/Production Process Equipment (in a plant)

Looking for Bauma China brand exhibitors?

Public Time: Oct 20, 2020

Public Company: POCLAIN HYDRAULICS

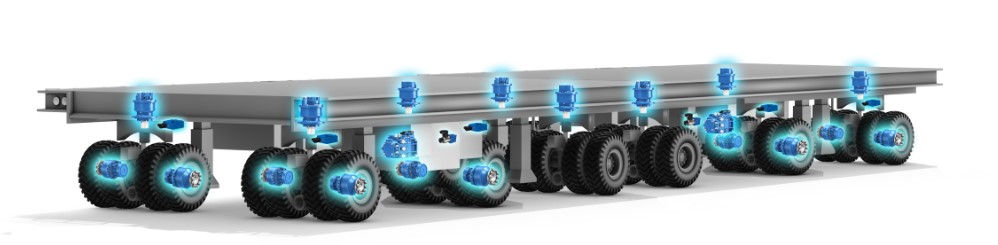

Multi-wheel

carriers or self-propelled modular transporters are rather unique vehicles

designed to carry heavy loads. They can propel independently and/or be used

on-road as semi-trailers and trailers. Self-propelled transporters operate in

relatively controlled areas such as shipyards, nuclear power plants or automotive

plants. Their versatility has given rise to their popularity, and the need for

efficient, smooth motion of large and heavy loads of critical or expensive

equipment spans a number of industries.

Developing

a self-propelled multi-wheel carrier presents a number of challenges:

· designing an efficient system

architecture to drive a large number of wheel motors together in a closed loop

· the space constraints for each

component

· meeting turning radius needs

· enabling synchronized movement with

multiple platforms either side by side or front to back

The type of

facility in which the machine will work and whether or not it will need to be

used on-road ultimately drives the decisions for its power transmission system.

Self-Propelled Transporters:

In a

parallel circuit, oil will take the path of least resistance. When there are

many wheels on the same circuit, the flow to the wheels can be irregular. As

flow affects speed, this presents a challenge for the OEM especially when

moving laterally. All wheels need to work together to move the machine at the

right rate to provide smooth and even mobility.

An antiskid system adapted to the multi-wheel carrier can help mitigate

irregular flow by ensuring that each wheel receives the precise amount of oil

needed at any moment.

Achieving

smooth and precise motion at low speeds is one of the biggest requirements for

multi-wheel carriers. Poclain Hydraulics’ cam-lobe radial piston technology can

run at speeds as low as 1kph—without cogging—delivering the smooth motion needed

for transporting fragile or sensitive but large material.

Another

challenge is fitting the right amount of torque, speed and safety functions

such as braking into the buggie’s envelope. The buggie’s envelopes are not

adapted to fit a gearbox. Each buggie is comprised of two wheels, which means

it must fit two motors.

Poclain Hydraulics Solutions for self-propelled

multi-wheel carriers:

In this

case, Poclain Hydraulics’ MHP motors with combined brakes fit the wheel motor

needs well. The MHP boasts three speeds. Aided by a directional control valve,

the MHP’s fluid transitions from one speed to another deliver the smooth drive

needed in this application. The MHP’s compact design makes it possible to fit

two motors in the buggie’s small envelope, whereas a motor and gearbox

combination would not be possible.

The

combined brake option available with the MHP motor consists of a service and

parking brake inside the bearing support. It allows for the necessary safety

features without taking up additional space.

A solution

for wheel orientation – a vertical MSE motor on a circular track – helps the

multi-wheel carrier achieve the steering and the crab motion necessary for

precise movement.

An

electro-proportional control pump, an electronic control unit and software to

pilot the system complete the Poclain Hydraulics offering, which integrates

easily into the machine’s electronic controls.

Gonzalo de Sebastián,

Sales and Marketing Director for DTA a designer and manufacturer of industrial

vehicles for in-plant transportation including multi wheel carriers on the

Poclain Hydraulics wheel motors:

The high efficiency of the new MHP motors

together with the capability of having three or four different displacements

with the Poclain automatic transmission, make this solution able to compete

successfully against variable displacement motors.

An advantage over variable displacement motors

is the possibility of having the motor, the gearbox and the dynamic and parking

brakes in a single compact unit.

To learn

more about power transmission solutions for multi wheel carriers as well as

other applications, visit Poclain Hydraulics at Bauma China 2020 in booth N4.

821, from November 24 – 27.