Construction

Vehicles

Construction vehicles

International Trade Fair for Construction Machinery,

Building Material Machines, Mining Machines and Construction Vehicles.

All

All

Construction

Vehicles

Construction vehicles

Earth-moving

Earth-moving machines

Road

Construction

Road construction and maintenance equipment

Lifting

Appliances

Lifting appliances and conveyors

Construction Equipment and tools, Formworks and Scaffolds

Pipe & cable laying equipment & tools/Construction equipment, tools and special systems/Formwork and scaffoldings

Mining, Extraction and Processing of Raw Materials

Machines for extraction of raw materials and for mining/Handling of raw materials/Mineral processing (incl. coke oven equipment)

Building Material Production

Handling and processing concrete and mortar at construction sites/Manufacture of cement, lime and gypsum compounds for building materials/Machines and systems for producing concrete, concrete products and pre-fabricated components/Machines and plants for producing asphalt/Machines and plants for producing pre-mixed Dry mortar, plaster, screed and building supply store products/Machines and plants for producing lime sandstone and building products using power plant residue (fly ash, slag, etc.)/Building material handling and packaging (in a plant)

Transmission Engineering and Fluid Technology

Transmission engineering, fluid technology and power generation units

Accessories, Spare and Wear Parts

Accessories and wear parts

Intelligent Management

Digital Construction Site and Job Safety/Services/Test, measurement and process control engineering/Communication and navigation/Production Process Equipment (in a plant)

Looking for Bauma China brand exhibitors?

Public Time: Oct 20, 2020

Public Company: POCLAIN HYDRAULICS

Poclain

Hydraulics currently offers complete on-road and off-road braking solutions. MHP

range motors are now available with service brake S17 and S20, parking brake

P17 and P20 and combine brake C27. Coupled with the VB3 valve range, they meet a

number of OEM requirements: low-pressure drop, space constraints, short

response time, safety, reliability and top performance.

Located in the bearing

support, the braking system of the MHP range keeps the overall solution’s axial

length under 44 cm for the MHP11 to 7 or under 50 cm for the MHP20 and 27! The MHP

is one of the more compact motors on the market.

The

new generation of oil-immersed brakes helps mobile machinery meet today’s

stringent road safety regulations.

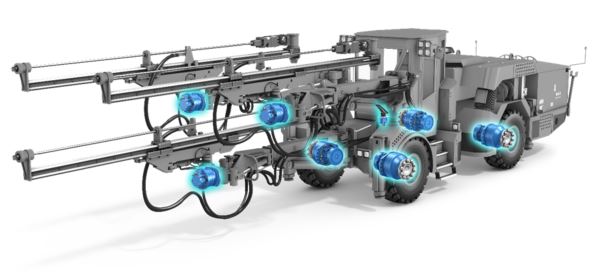

- In underground mining machines such as jumbo drilling in China or tunneling

jumbo from Sandvik for example, subject to anti-explosion regulations and long descents

that call for a high performance wet brake solution.

-

In

agriculture, 4000L sprayers are required to stop in under 20 meters, and have a

braking time below three seconds traveling at 40 kph.

To meet safety requirements, vehicle-braking systems

features need to have a secondary braking system to use if the primary one

fails: embedded in the S17 and S20 service brake the patented double control

command offers full redundancy over the braking command.

Field-proven MHP

excellence

Numerous OEMs worldwide from agriculture, construction,

material-handling equipment to utility installation equipment such as HDDs, and

other mining, marine or industrial applications have switched to the MHP series.

The High-Performance range of products aims to set a standard for cam-lobe

motor technology in terms of performance, reliability and efficiency. At

equivalent displacement, the MHP series can transfer up to three times more

power than the standard MS range.

In just two years, the MHP has equipped thousands of machines

and over 50 customers. Beyond being qualified to operate up to 500 bar, the MHP

range has seen success thanks to its very stable high performance regardless of

displacement and speed, exceeding 90% overall efficiency over a broad operating

range. With the MHP range, radial piston technology expresses best-in-class

heavy-duty potential. The latest models MHP13 to MHP17 are taking off for

promising success with smaller displacements and higher speeds.

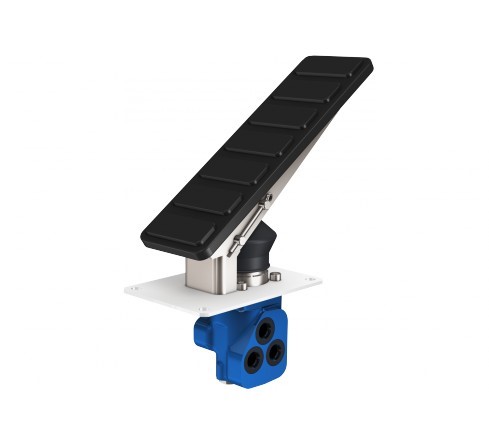

VB3 valves for single

or dual brake circuits

The VB3 valves are smart, robust and extremely compact.

They are the most compact range on the market. The VB3-20 weighs 43% less than

its predecessor, and is the shortest dual circuit valve on the market. The VB3

range also answers to geographical or OEMs specific braking regulations.

VB3 valves address single and dual brake circuits.

They use a wet spring box and have options for larger ports on the same

housing, making them a strong option for heavy machinery. A lower pressure drop

(7.5 bar for the VB3-020) and pressure tolerance (less then +/- 3 bar), a

higher flow rate (up to 50 l per minute) and maximum inlet pressure (up to 250

bars) enhance performance.

The casted boby and flexible design (vertical or

horizontal position) making it easier to integrate. All the Poclain Hydraulics

dual circuit valves in the VB range have the same fixation points and connect

to the same actuators. They facilitate interchangeability making the benefits

of the new design accessible for a wide range of machines: loaders, excavators,

site dumpers, mining equipment, forklift trucks, telehandlers, forestry

machines, mowers, airport equipment and cranes.

All VB3 valves come standard with reinforced sealing

and a wet spring box to avoid external pollution and prevent rust. It houses

parallel-mounted spools. Oil contamination is always a hazard, but in the event

that one spool becomes stuck because of contamination, the other spool will

still actuate the brake.

Poclain Hydraulics will be present at Bauma China in

booth N4. 821.Contact us to

set up a meeting at the show to learn more about this and other

solutions.