Construction

Vehicles

Construction vehicles

International Trade Fair for Construction Machinery,

Building Material Machines, Mining Machines and Construction Vehicles.

All

All

Construction

Vehicles

Construction vehicles

Earth-moving

Earth-moving machines

Road

Construction

Road construction and maintenance equipment

Lifting

Appliances

Lifting appliances and conveyors

Construction Equipment and tools, Formworks and Scaffolds

Pipe & cable laying equipment & tools/Construction equipment, tools and special systems/Formwork and scaffoldings

Mining, Extraction and Processing of Raw Materials

Machines for extraction of raw materials and for mining/Handling of raw materials/Mineral processing (incl. coke oven equipment)

Building Material Production

Handling and processing concrete and mortar at construction sites/Manufacture of cement, lime and gypsum compounds for building materials/Machines and systems for producing concrete, concrete products and pre-fabricated components/Machines and plants for producing asphalt/Machines and plants for producing pre-mixed Dry mortar, plaster, screed and building supply store products/Machines and plants for producing lime sandstone and building products using power plant residue (fly ash, slag, etc.)/Building material handling and packaging (in a plant)

Transmission Engineering and Fluid Technology

Transmission engineering, fluid technology and power generation units

Accessories, Spare and Wear Parts

Accessories and wear parts

Intelligent Management

Digital Construction Site and Job Safety/Services/Test, measurement and process control engineering/Communication and navigation/Production Process Equipment (in a plant)

Looking for Bauma China brand exhibitors?

WURTH ELEKTRONIK ICS (SHENYANG) CO., LTD.

Booth No. W5.776

Headquarters:

Target Groups:

Product Category: Electricity equipment for vehicles

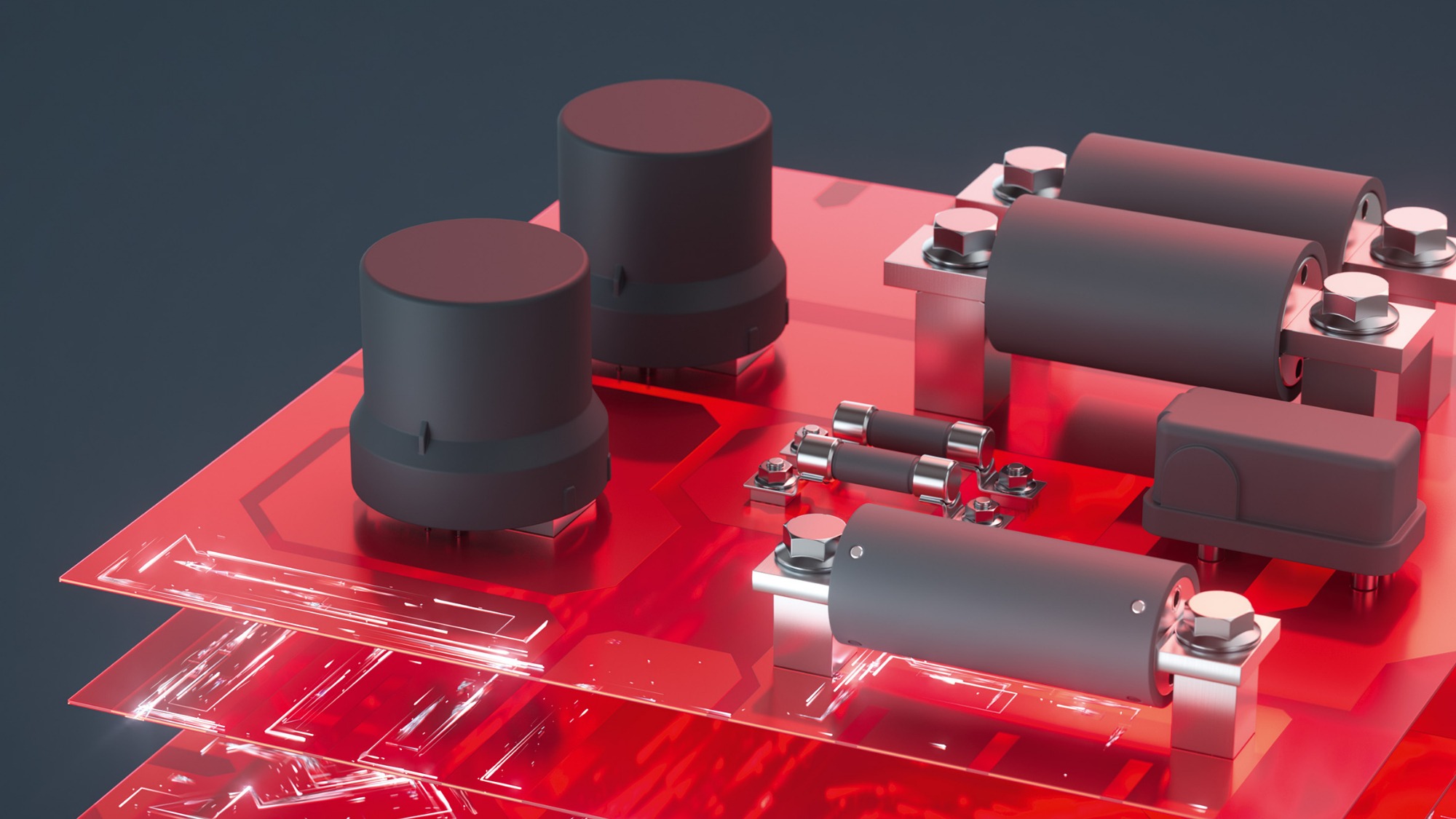

The trend towards electromobility is present throughout the world of mobile machinery and commercial vehicles. There is hardly any vehicle manufacturer that does not deal with this topic. As a development partner and supplier of power distribution systems for these industries, Würth Elektronik ICS assists and helps its customers to implement new machines with alternative drives. With its High Voltage Power Distribution Units (HV PDUs), the company offers solutions for power distribution up to 1000 V that are compact, robust and can also be flexibly configured.

In developing its HV PDUs, Würth Elektronik ICS is able to draw on its decades of expertise in the areas of high-current management and press-fit technology. This technology has proven to be particularly beneficial in the series production phase. Many well-known manufacturers of mobile machines and commercial vehicles have implemented successful projects and are now impressed by the advantages of PCB-based HV PDUs.

Press-fit technology offers major benefits

‘We have enormous expertise when it comes to connecting components to the PCB and we have our own portfolio of connectors and Powerelements using press-fit technology. This allows us to connect a wide variety of HV components to the circuit board and so map a large number of safety-relevant and diagnostic functions,’ explains Ludovic Frelin, Product Manager for HV solutions at Würth Elektronik ICS.

Press-fit technology makes it possible to implement compact and robust solutions that have proven to be reliable and successful under extreme operating conditions. Low contact resistance leads to high current-carrying capacity and low heat generation. Power distribution solutions with press-fit technology also offer a decisive advantage in the series production phase as the need for time-consuming and error-prone wiring is eliminated. Often, the cables can simply be connected using plug-and-play. Maintenance is just as easy.

Power distributors in the high-voltage range

The HV PDUs from Würth Elektronik ICS ensure stable and secure connections in the voltage range of 60 VDC to 1000 VDC for an optimal distribution of power between battery, on-board charger, inverter and other consumers such as heaters or DC/DC converters. The compact power distributors are fitted in carefully sealed, corrosion-proof housings and allow important components and functions to be integrated. These include: fuses and protective devices, pre-charging functions, current, voltage and temperature measurement, insulation monitoring, HVIL and shielding. Parts of battery management can also be integrated into PDUs. This reduces the overall size of the system and makes it more reliable.

Further control and diagnostic functions can be added by integrating controllers into the HV PDUs. Here too, Würth Elektronik ICS draws on its many years of expertise in electronics development and offers customized control modules for the HV PDUs on customer request.

'Power distributors are one of the few components in the HV electrical system that are developed individually for each vehicle,’ explains Ludovic Frelin. ‘We offer a complete service with electromechanical and electronic design, from concept to series production, hardware development, software development, testing and qualification. This way, we can help our customers – including many start-ups in the field of e-mobility – to achieve their ambitious goals.’